Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

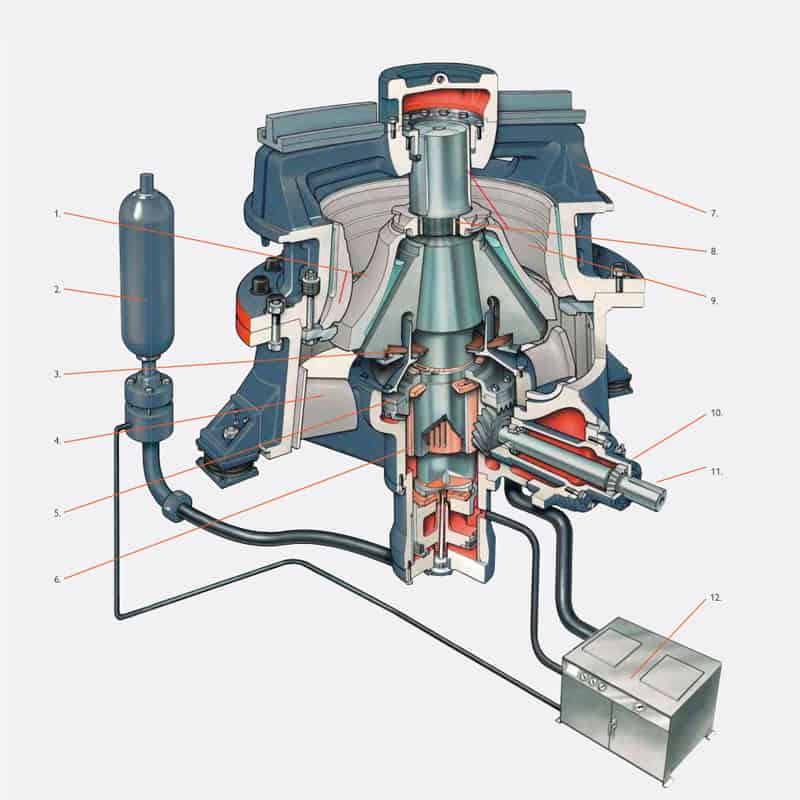

Cone crusher also uses very broad, typically used in the field of metallurgy, mining, water and the like in buildings, play a key role in the production process. The main working object of the crushing machine is ore material, and its grain shape (geometry of material particles) is the main index for the quality evaluation of broken products, and can be generally divided into cubic shape and needle shape.

The mass fraction of the needle-shaped particles in the broken product is the needle ratio, which is a quantitative index for evaluating the shape of the broken product. The main factors affecting the needle rate include ore type, crusher type, crushing stage, feed size, closed-end discharge port size (CSS), material feed rate, and eccentric shaft speed.

In the construction field, the increase of the needle-like particles in the concrete aggregate will lead to a decrease in the overall compressive strength of the building and increase the cement consumption during the construction process; likewise, in the asphalt mixture, the increase of the needle-like particles will also This results in a decrease in the overall density of the mixture and the compressive and tensile strength. It can be seen that the needle ratio has an important effect on the quality of the broken product.

Next, explain the control of the pinch rate of the cone crusher crushing product:

When the material passes through the crushing chamber of the cone crusher, its needle pin rate increases rapidly with the occurrence of crushing and crushing events, and reaches a certain level and then gradually falls back. Combined with relevant research at home and abroad, the material becomes more uniform after entering the crusher after screening or particle separation process; after entering the crushing chamber, the material is crushed and crushed, and the needle-like particles begin to appear. The more material particles are crushed and crushed, the needle-like particles increase rapidly; when the crushing event is further increased, some of the material particles including the needle-like particles begin to be subjected to two or more pressing actions.

In the second half of the crushing process, the pinch rate of the material in the crushing chamber drops and returns to the desired range. It can be seen that during the working process of the cone crusher, the frequency of the crushing and crushing event increases, which is beneficial to reduce the needle-like particles in the broken product. Therefore, the increase in the spindle speed can improve the grain quality of the crushed product to some extent.

It can be seen that measures such as increasing the spindle speed, improving the structural parameters of the crusher and increasing the probability of occurrence of crushing events in the crushing chamber (number of repeated crushing of materials) are effective ways to improve the shape of the crushed product.

इस आपूर्तिकर्ता को ईमेल

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.